Before You Start: The Pre-Operation Checklist

Your safety begins before you even pull the trigger. Make these steps a routine part of your workflow:

- Read the Manual: Always start by reading the manufacturer's operation manual for your specific spray foam gun. Every model has unique features and requirements.

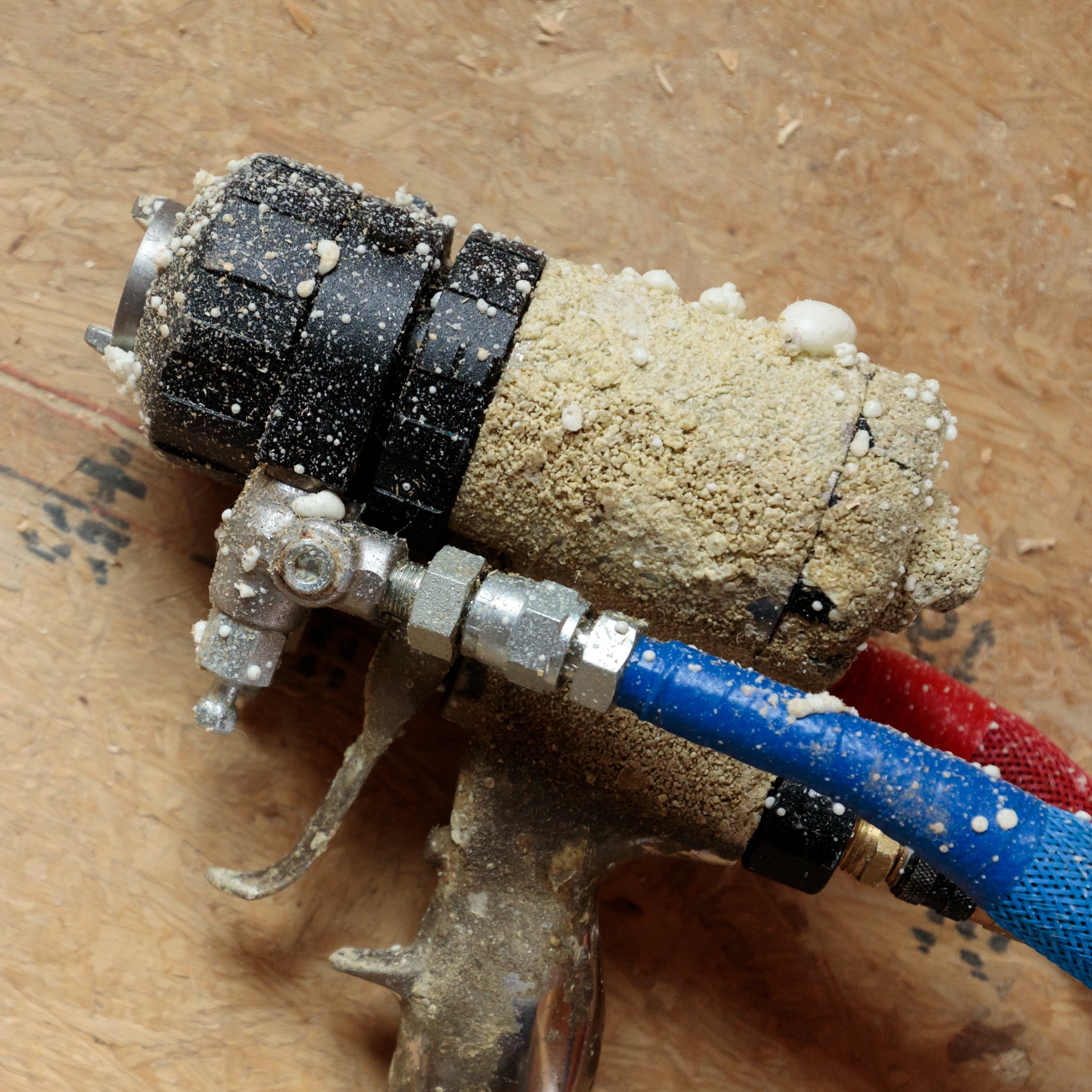

- Inspect Your Equipment: Before each use, inspect the spray gun for any signs of damage or wear. A compromised gun is a dangerous gun.

- Check Connections: Verify that all hoses and connections are secure and free of leaks. High-pressure leaks can be extremely hazardous.

- Confirm Pressure and Temperature: Ensure your air compressor and material pumps are functioning correctly and are set to the recommended pressures. Proper pressure and temperature are crucial for safe and effective material atomization.

- Cleanliness is Key: Check that the spray gun is clean and free of cured foam or debris. A clean gun prevents clogs and unexpected spray patterns.

During Operation: Stay in Control

The application process requires your full attention. Follow these rules to maintain control and prevent accidents:

Proper Grip and Stance: Maintain a firm grip on the spray gun at all times.

Finger Off the Trigger: Many guns have a safety lock. Use it when the gun is not in use. To prevent accidental discharge, keep your finger off the trigger until you are ready to spray.

Point with Caution: Always keep the spray gun pointed away from your body when not actively spraying.

Handle Malfunctions Safely: If the gun jams or malfunctions, stop spraying immediately. Never attempt to clear a clogged nozzle with your hands or fingers. Use the appropriate tools and follow manufacturer guidelines for troubleshooting.

After the Job: Proper Cleanup and Storage

Your work isn't done until the equipment is safely stored. This ensures the gun is ready for the next job and prevents long-term damage.

Thorough Cleaning: Clean the spray gun according to the manufacturer's instructions.

Relieve Pressure: Relieve all pressure from the spray system before storing the gun. This is a crucial step to prevent unexpected discharge.

Secure Storage: Store the spray gun in a clean, dry, and secure location, away from unauthorized access.

Routine Maintenance: Perform routine maintenance as recommended by the manufacturer. This keeps your gun in optimal condition and extends its life.

Emergency Procedures: Be Prepared for Anything

No matter how careful you are, emergencies can happen. Knowing what to do in a crisis can be a lifesaver.

High-Pressure Injection: In the event of a high-pressure injection injury, seek immediate medical attention. This is a serious injury that requires professional care.

Chemical Exposure: For accidental skin or eye contact, follow the instructions on the chemical's Safety Data Sheet (SDS). Move to fresh air immediately if you experience inhalation exposure to fumes.

First Aid and Spill Kits: Always have a first aid kit and spill control kits readily available on the job site. All workers should be trained in proper spill response procedures.